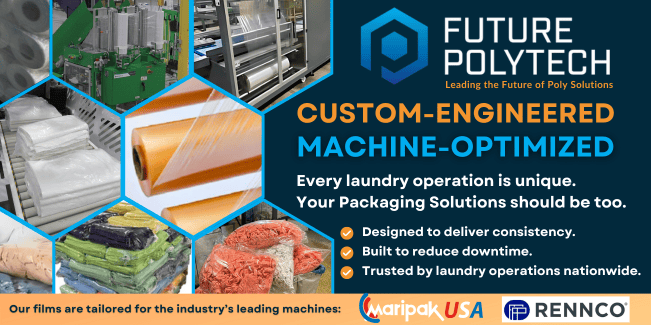

Simple Equipment, Sophisticated Style

Metro Laundry Service exceeds Luxury Hotel

Brand expectations with LAVATEC equipment

Beacon Falls, Conn. – December 3, 2025 – The nation’s capital in Washington D.C. is more than just the federal home of government in the United States. It is also one of the most competitive markets for the hotel industry. In addition to catering to a broad range of corporate visitors who attend business meetings, hotels in the District of Columbia also serve many domestic and international leisure travelers and government workers.

For nearly a quarter century, Metro Laundry Service (MLS) has gradually grown while making its mark. They expanded from newcomer status to a highly respected player in the metro area by winning new business and delivering outstanding service to brand name luxury hotel customers. And they’ve accomplished this level of success with the help of wash aisle equipment from Lavatec Laundry Technology.

A tradition of community excellence

Metro Laundry Service in Capitol Heights, Maryland is the only wholly family-owned certified Minority Business Enterprise commercial laundry business in the metro D.C. area specializing in the needs of hotels. CEO Bernard Young started the business in a small, 1500 square-foot rental property on the east side of the city in 2004. Today, their 24,000 square-foot facility is located not far from Northwest Stadium, home of the NFL Washington Commanders football team.

Bernard’s nephew, Steven Young, serves as the company’s Chief Operating Officer. When he completed his education at Baltimore’s Morgan State University in 2004, he joined MLS the same year it opened and began working as a supervisor. In his current role, he manages various aspects of daily operations and new business development.

“I majored in IT and ended up a laundry guy. Go figure,” quipped Steven Young. “In 2004, I was one of 10 employees and it was not what I set out to do. I only planned on working here for a short period of time to help my uncle get the company off the ground.

“At the time,” continued Young, “I think we needed each other. I needed to work and have a steady income until I figured out my next move, and Bernard needed someone he could trust to oversee the operation while he was away. He has been very influential in my personal success and growth within the company. Observing him handle various aspects of the business during the early years has helped me handle the same or similar situations I encounter now.”

One situation no one was prepared for was the COVID-19 pandemic in early 2020. MLS had leased a second facility in Elkridge, halfway between Baltimore and Washington D.C., in October 2018 to help expand the business. By 2021, after the pandemic had significantly impacted the hotel and travel industries, they closed the location and consolidated all of the work in Capitol Heights.

But adversity has only made the MLS team stronger. Servicing chain brands such as Hilton, Hyatt, Marriott and MGM, they now employ 140 people and run two shifts daily. Young indicated 85 percent of the work is hotel room linens, as well as some food and beverage and a small fraction of spa work.

In 2024, MLS processed approximately 22 million pounds of laundry and are on pace to finish this year with a similar amount. Depending on some government related factors, Young anticipates the volume could grow to 24 million pounds in 2026. He pointed out favorable developments in the second half of 2025 that could result in more work.

In June, Metro Laundry Service was honored with the prestigious Governor’s Citation Award. The Maryland Governor’s office of Small Minority & Women Business Affairs recognized the company for its leadership and outstanding contributions to the Minority Business Enterprise small business community in the state.

Last month, MLS was named the Supplier of the Year by MGM National Harbor Hotel & Casino. The popular entertainment destination resort is located south of downtown in Oxon Hill, on the eastern shore of the Potomac River.

“Winning this award reflects the dedication, expertise, and hard work of our team, and we were honored to win the Governor’s Citation Award,” acknowledged Young. “Being a certified MBE is very important to us, and we try to partner with other MBEs as much as possible for service and operational needs.”

Since his early days at MLS, Young said management has always maintained a strong commitment to its staff.

“We work with our local state and county organizations to help employ local people in the community. People in our industry know that maintaining low turnover is very difficult considering the nature of the job and labor required,” he said, explaining further that MLS organizes and supports annual cookouts, holiday parties and other events.

“Knowing that laundry is not a glamourous job or career path, we try our best to maintain a family-like atmosphere. Having several tenured employees for 10-plus years is a testament to the culture we maintain and something we are very proud of.”

Fourteen years of Improved consistency, productivity, and efficiency

Several key factors have helped MLS to earn and retain their hotel customers’ business. There is the cutting-edge stain identification and removal technology, the continuous linen monitoring and RFID-tagged linen technology, and the 24/7 continuous support they provide day in and day out.

Driving that kind of reliability is both new and used LAVATEC equipment, from the wash stage through the drying phase. An LT60 15 compartment bottom transfer tunnel washer with 132-pound capacity per chamber spans the better part of three decades. Built and entered into service in 1993, MLS bought the remanufactured machine in 2012.

“It has been running strong ever since, which we believe is a testament to the quality of the machine and LAVATEC brand,” said Young. “We chose them based on the positive feedback we got from other colleagues in the industry. I’m very pleased our experience with their tunnel washer systems lived up to what we were told. With future growth plans, it is very likely we will seek to acquire another LAVATEC tunnel washer.”

LAVATEC is known for designing and engineering simple equipment, which enhances its reputation for delivering reliable and long-lasting machines. Young said that a couple of years ago, they added another LAVATEC gas dryer (to the six already on the floor) and bypass to reduce the number of times the tunnel washer goes on hold.

“It also gave us some flexibility,” he noted, “in case a dryer goes down.”

More recently, MLS upgraded their 40-bar, LP572 extraction press to a 50-bar LP581S LAVAPress single stage extraction press. It handles 132-pound loads and, according to Young, has improved workflow and provided other benefits.“The upgrade to the 581S press allowed us to reduce our cycle transfer times to the mid-70 seconds so we are able to average 40-plus transfers per hour, which has increased our washed pounds per hour and capacity,” stated Young.

“It has resulted in significantly reduced drying times due to the decreased moisture retention and hourly capacity. Overall, this has a direct impact on the bottom line since it helps reduce our utility costs and increase our pounds per operator hour (PPOH).”

Young indicated the dependability of LAVATEC’s equipment and team make it easier for MLS staff to get the job done and keep customers happy.

“When servicing our hotel customers, there are no days off. There are standard primary maintenance functions we follow for maintaining the tunnel system, the dryers, and their components, so it really comes down to the engineering team and how that department is managed,” he explained.

“Overall, the downtime we have experienced with the LAVATEC tunnel system has been minimal. When we needed their assistance, they have been responsive. The LAVATEC team, including service manager Edwin Schrijvers, and regional sales manager Eric Schori, have been instrumental in helping us navigate through any issues and maintaining open communication with our team.”

About Lavatec Laundry Technology, Inc.

Delivering dependable commercial laundry equipment engineered for higher returns throughout their lifecycles has been the Lavatec Laundry Technology mantra for over four decades. Some LAVATEC manufactured equipment has been on the job for more than a quarter century. A rarity among manufacturers of continuous tunnel washers, LAVATEC offers center transfer, bottom transfer and standing bath construction options, plus a full range of readily integrated, end-to-end laundry system components: washer extractors, extraction presses, centrifuges, dryers, conveyor systems, pickers, feeders, ironers and folders. Simple design, durable construction, user-friendly operation and low maintenance are hallmarks of LAVATEC machines. A global leader with equipment in laundry operations throughout Europe, the Far East, South and North America, more than 8,000 LAVATEC machines have been installed in the United States alone. For more information, visit www.LLTusa.com.

Steven Young, CEO of Metro Laundry Service

A Metro Laundry Service operator makes adjustments to the 15 compartment LAVATEC tunnel wash system the company has run since 2012.

In addition to the tunnel washer and extractor press, Metro Laundry Service utilizes LAVATEC gas dryers as part of it’s operation.